Optimization is, among other things, about maximizing the value of a resource or making the most effective use of it. If, for example, a widget-making machine—under favorable conditions—is capable of producing between 900 and 1,000 widgets per-hour, but in your organization the widget-making machine is only producing 600 widgets per-hour, then it is safe to say that the machine is not optimized (i.e. it is producing widgets at a sub-optimal level).

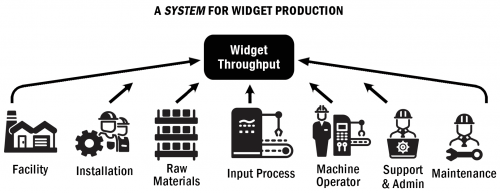

So how does the widget-machine-owning organization begin to optimize the performance of the machine? The organization must first acknowledge that widget-production is not simply a matter of speeding up the widget-making machine, but is instead a process of optimizing the widget-production system. In this context, I am using the term “system” to describe a collection of interrelated, interdependent components that act in concert to turn inputs into outputs in pursuit of a goal. So, if a manufacturing goal is to churn out between 900 and 1,000 widgets per-hour, then the organization must consider all of the elements of the system that can impact the production of widgets. This is illustrated in the diagram below.

In this example, if the goal of the organization is to increase and optimize widget production, the organization would have to consider all of the levers of widget production beyond the widget-making machine, such as the quality of the raw materials being used; the process for inputting the materials into the machine; the quality of the machine’s installation; the preparedness of the environment and the conditions in which the machine will operate; the skill of the machine operator; the system support provided; and the maintenance and upkeep of the machine. If any one of these levers of optimization is sub-optimal, the output production level of the widget-making machine will be diminished. Therefore, if the organization wants to optimize widget production, it must consider the impact of all of the aforementioned levers of widget production on output levels.

This idea of optimization and the impact of various parts of a system on productivity and performance not only applies to machinery, but also applies to any job function, role, or responsibility where the process of performing those activities can be defined and mapped.

If, for instance, an organization’s leadership wants to optimize the work performance of its sales associates, the leaders must first identify all of the levers that impact the sales associates’ ability to deliver the desired sales outcome: a tremendous Customer Experience (CE). When they do, the leaders will acknowledge that delivering a positive CE and creating loyal promoter customers is more than simply a function of helping the sales associates improve their ability to navigate the sales cycle.

Optimizing sales effectiveness is a function of the many variables that are all part of the system of selling. This can include (but is not limited to) the organization’s goals and objectives; product development; product & program management; marketing; operations; sales operations; non-productive activities (e.g. email and administrative tasks); sales talent; selling support; and product support to name a few.

For many organizations, the “low-hanging-fruit” toward optimizing sales productivity is reducing sales detractors—those activities in which a seller engages that, while often necessary, do not move the sales process forward but instead, slow the sellers time-to-close, reduces overall sales performance, and negatively impacts work-life balance. Based on the findings of a recent study I conducted on sales effectiveness, the top-5 non-selling activities in which a typical sales professional engages (excluding travel time) revolve around internal communication:

1. Managing email

2. Completing requests for information

3. Conference calls

4. Phone conversations (internal)

5. Standard sales reporting

The findings revealed that it was not uncommon for many study participants to spend upward of 4 hours per day handling email communications.

Sales detractors are but one lever that negatively impacts a sales professional’s ability to optimize her or his performance. Ultimately, optimizing a worker’s productivity and ultimately their effectiveness requires an understanding of systems and how the elements of a particular system positively or negatively impact a worker’s ability to perform at the highest levels possible.